Error loading player: No playable sources found

3552786

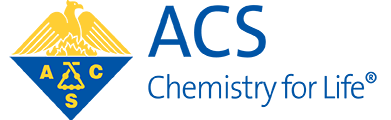

Functionalized δ-hexalactone (FDHL) monomers to synthesize higher Tg aliphatic polyesters

Date

April 9, 2021

Related Products

Exploring grafting-through polymerization as a method for the surface functionalization of renewable cellulosic nanomaterials | Poster Board #3748

The grafting of polymeric materials to colloidal surfaces is ubiquitous in materials science, to introduce new reactivities, to achieve improved stability, or to incorporate stimuli responsiveness, amongst other goals…

Surfactant free grafting-through emulsion polymerizations to modify the surface of cellulose and create reinforcements for thermoplastics and rubbers

Biobased fibers can be used to reinforce many thermoplastics, reducing the amount of non-biobased content required, provided they can be effectively dispersed and compatibilized…

Fibrillated bleached softwood kraft pulp modified via grafting-through polymerization

A fully aqueous grafting-through polymerization approach was employed to apply various polymeric surface modifications to bleached softwood kraft pulp (BSKP)…

Harnessing polymer grafted cellulose nanofibrils as scalable reinforcements for composite additive manufacturing

Mechanically refined cellulose nanofibrils (CNFs) promise a high-volume, low-cost nanoscale reinforcement for biodegradable PLA composites aimed at large scale additive manufacturing. There are a multitude of challenges slowing the utilization of these materials though…