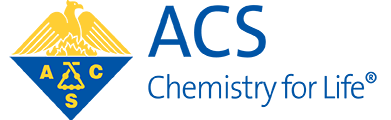

Promotional role of Ni-Cu alloy in catalytic performance and carbon properties for CO2-free H2 production from thermocatalytic decomposition of methane

Related Products

Promotional role of Ni-Cu alloy in catalytic performance and carbon properties for CO2-free H2 production from thermocatalytic decomposition of methane

While water electrolysis (H2O(l) → H2 + ½ O2; ΔH° = 286 kJ/mol H2 ) holds promise for the generation of CO2-free hydrogen (H2), the high energy intensity and cost of electricity hinder their widespread utilization for H2 generation…

Promotional role of Ni-Cu alloy in catalytic performance and carbon properties for CO2-free H2 production from thermocatalytic decomposition of methane

While water electrolysis (H2O(l) → H2 + ½ O2; ΔH° = 286 kJ/mol H2 ) holds promise for the generation of CO2-free hydrogen (H2), the high energy intensity and cost of electricity hinder their widespread utilization for H2 generation…

Promotional role of Ni-Cu alloy in catalytic performance and carbon properties for CO2-free H2 production from thermocatalytic decomposition of methane

While water electrolysis (H2O(l) → H2 + ½ O2; ΔH° = 286 kJ/mol H2 ) holds promise for the generation of CO2-free hydrogen (H2), the high energy intensity and cost of electricity hinder their widespread utilization for H2 generation…

General Catalysis: C1 Chemistry

: [CATL] Division of Catalysis Science & Technology