3911595

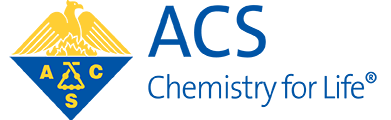

From free radical to radical-free lithographic 3D printing

Date

August 14, 2023

Explore related products in the following collection:

Related Products

PMSE Business Meeting

DIVISION/COMMITTEE: [PMSE] Division of Polymeric Materials Science and Engineering

Approaches to ion-containing, mesoporous, and nanostructured materials using block polymers as vital components

The self-assembly of block polymers is very powerful for the design of mesoporous and other nanostructured materials…

Functional group metamorphosis in the condensed state: A self-reinforcing mechanism to increase mechanical performance of thermoplastic polyurethane materials on demand

We show that tuning the kinetics of a dynamic hindered urea bond in polyurethanes to match competitive isocyanate hydrolysis results in the formation of new, unhindered urea bonds upon incubation of the material in water (Figure 1)…

Award Address (ACS Award in Polymer Chemistry sponsored by the ExxonMobil Chemical Company). Advanced characterization methods, precise polymers and simulations combine to advance the understanding of ion conductivity in ionomers

Ionomers are a diverse array of polymers having a mixture of ionic and non-ionic moieties and were originally valued for their tough mechanical properties and good chemical resistance…