Exploring subcritical and supercritical oxidation as pretreatment techniques for membrane separation to recover high-value hydrocarbons from byproducts of hydrothermal liquefaction: A mathematical model

Related Products

Integrating thermochemistry, synthetic biology, and public policy to upcycle the fugitive carbon in hydrothermal liquefaction process water

Wet biomasses such as sludge, manure, agro-industrial processing and food waste are moisture-rich, “low-carbon” wastes. Such feedstocks are typically managed via anaerobic digestion (AD). Yet AD is a suboptimal conversion pathway owing to long residence times and limited recoverable products…

Exploring subcritical and supercritical oxidation as pretreatment techniques for membrane separation to recover high-value hydrocarbons from byproducts of hydrothermal liquefaction: A mathematical model

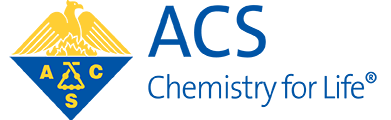

Agriculture leads to significant waste generation (chicken/cattle manure, food waste, and lignocellulosic biomass). Valorization of these wastes into useful chemicals is important for transitioning to a circular bioeconomy…

AIChE/ACS Frontiers of Chemistry, Materials Science & Chemical Engineering for Circular Economy:

: [ENVR] Division of Environmental Chemistry

AIChE/ACS Frontiers of Chemistry, Materials Science & Chemical Engineering for Circular Economy:

: [ENVR] Division of Environmental Chemistry