3826922

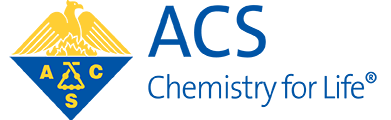

Control of poly(phenylene sulfide) morphology and mechanical behavior from a TIPS system via nucleation density manipulation

Date

March 28, 2023

Related Products

Influence of thermal annealing on the morphology and toughness of poly(phenylene sulfide) aerogels

Polymer aerogels derived from engineering thermoplastics provide good mechanical properties and high chemical and thermal stability through highly-porous, low-density monolithic structures…

Control of poly(phenylene sulfide) morphology and mechanical behavior from a TIPS system via nucleation density manipulation

Polymer aerogels are highly porous, low-density solids often used in filtration, separation, and insulation applications…

Morphological control of poly(ether ketone ketone) as a means to tailor blocky functionalization in the gel state | Poster Board #1241

Block copolymers derived from engineering thermoplastics provide high chemical and thermal stability and good mechanical properties as well as micro-phase separated morphologies that can significantly enhance material properties…

Polysaccharide – based block copolymers for sustainable bioplastics

Synthetic plastics, which exhibit a wide range of physiochemical properties at a low cost and enable the production of a plethora of useful products, are inherently unsustainable: they require expensive end-of-life management with low consumer compliance; they resist biodegradation; they persist in…